Reciprocating Friction Tester solution|linear wear friction testing : vendor The TR 282 Series Reciprocating Friction Monitor is especially designed to study friction characteristics of materials. reciprocating engine is used to create a bidirectional sliding motion . webMiga World Android. 1.68. бесплатно XAPK 8,1 300 Проверенная безопасность. Если вы с детства мечтали создать свой игрушечный мир, вашему ребенку повезло. Miga World - открытый мир для детей с настраиваемыми .

{plog:ftitle_list}

webWith our responsive app, physical stores and online shops, who have been accepting card payment of all types : credit, debit, charge, prepaid, etc;are able to access very important data about payment cards from consumers. Our up-to-date BIN List database can effectively returns the card type, scheme, network, country, and some to all issuer .

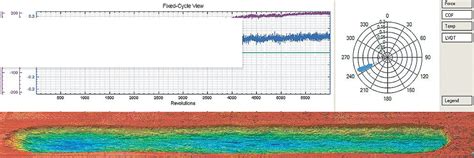

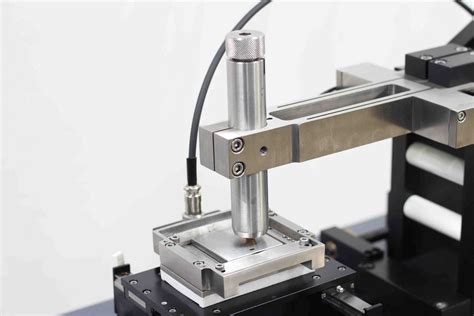

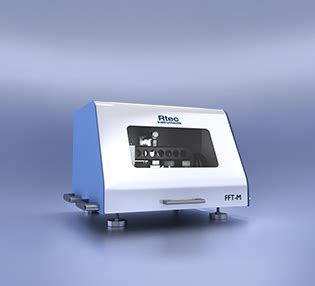

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module accommodates several application specific chambers, fixtures and test .Evaluate fuel lubricity, predict the performance of additives, and study .Evaluate fuel lubricity, predict the performance of additives, and study friction wear with our HFRR high frequency reciprocating rig. This next generation Rtec Instruments HFRR testing machine contains programmable force control (no .

The TR 282 Series Reciprocating Friction Monitor is especially designed to study friction characteristics of materials. reciprocating engine is used to create a bidirectional sliding motion .

In addition to tailored hardware components, these modules feature software developed in conjunction with industry-leading manufacturers to address targeted standards. Bruker’s .Bruker’s High Frequency Reciprocating Rig (HFRR) Module for the UMT TriboLab™ Mechanical Tester enables a versatile and cost-effective way to screen lubricants and materials at the .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance .

The TE 77 High Frequency Friction Machine is a versatile reciprocating tribometer with a maximum stroke of 25 mm and maximum load of 1,000 N. It is now a well-established research and development tool for evaluation of .This next generation High Frequency Reciprocating Rig HFRR test module has real-time programmable force control, piezo sensors to measure real time friction, in-line total wear scar depth, wide temperature range, and voice coil .The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. The aim of this work is thus to develop a novel reciprocating tribometer and test method that enables friction and wear tests under low-speed reciprocatory sliding with contact pressures up to 90 MPa in a flat-on-flat .

2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has .

linear wear friction testing

Testing and measurement of friction, wear, and material mechanical properties Tribometers and Mechanical Testers Research into materials and how materials can be changed to influence strength, integrity, or durability is an integral part . A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions .

tacklife mwm02 digital wood moisture meter

Rtec’s Tribometer SRV test system measures the coefficient of friction and wear between a lubricant, oil, grease, and two specimens in a loaded contact in linear oscillatory motion from 5 micron strokes. The sliding reciprocating friction module has a wide load, speed, and temperature range. A reciprocating friction and wear tester based on Lab VIEW was designed and built to preliminarily test the friction and wear characteristics of different materials under different test conditions and lubricant additives. The mechanical structure and measurement, and control system were optimized. It carried out functional test studies. The test shows that the test . Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004

In the present work, effects of significant factors on friction coefficient and friction force are analyzed on reciprocating friction and wear test rig (RFWTR) by using Taguchi approach. The Taguchi method (TM) is employed for evaluate the experimental work, analyzed the effect of working parameters for the PRA and decides the influence of .The tester is used to simulate the rotation and linear reciprocating motion under a certain test force. It is tested by controlling and changing the test force, speed, frequency, stroke, time, friction partner material, surface roughness, hardness and other parameters to evaluate the comprehensive performance of the material or surface coating.The machine uses weight loading 50g-2000g; automatic constant loading; dynamic alternating loading: (sine wave loading, triangle wave, gradient loading) three loading modes, which can simulate point, line, and surface contact forms to reciprocate to achieve different test force, friction frequency, friction coefficient and other friction .

linear friction tribometer test

Simple reciprocating friction and wear tester D.F. Moore* and S. Noah+ This paper describes a simple and accurate friction and wear bench machine which can also be used for fatigue testing. . a compromise solution has been adopted in that the main loading block in Fig 3 can be positioned laterally as desired by moving along the transverse .The requirement was to develop a test methodology that would quickly deliver differentiable and reproducible friction and wear results. Oscillation was chosen as the test motion, which, in combination with the test force, ensures the most realistic and practical stress conditions possible – at that time, one of the first fretting tests worldwide.

Bruker’s High Frequency Reciprocating Rig (HFRR) Module for the UMT TriboLab™ Mechanical Tester enables a versatile and cost-effective way to screen lubricants and materials at the benchtop scale. Traditionally, the testing of surfaces and lubricants on reciprocating systems, such as engines and linear compressors, has required the use of laboratory-scale tribometers . Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension .

2.Set the test parameter: Stroke length, reciprocating frequency, friction, test temperature and test time. It also can do the course setting to each parameter. 3.Control the mechanical part running time, it can keep monitoring the stroke length, reciprocating frequency and .

The equipment has two forms of motion, so it includes two test modules, which are easy to replace and can meet more test requirements. Rotating module: The equipment moves in a rotating way to achieve a variety of friction contact .This next generation High Frequency Reciprocating Rig HFRR test module has real-time programmable force control, piezo sensors to measure real time friction, in-line total wear scar depth, wide temperature range, and voice coil .

5.Current-carrying friction components (1) Testing friction current:50A (2) Dynamic in-situ and synchronous real-time friction coefficient measurement (3) Dynamic in-situ, synchronous, real-time friction current test (4) Dynamic in-situ, synchronous, real-time friction coefficient, and friction current display. 6.Oil / grease lubrication componentsDescription. This tester is focused on wear testing evaluation by visual inspection. The Basic Grade Type: 30, and the Type: 30S with non-staged high speed adjustment function and specified rotation number auto stop function, are available.In addition, the 2-series and 4-series specifications, where testing can be carried out a number of times under similar conditions, .

Coefficient of Friction (COF) is the maximum value of the frictional force divided by the normal force. Coefficient of Friction (COF) testing is used for a variety of materials from lubricants, to films and household items (ceramic tiles) to determine the frictional characteristics of a material.

high frequency friction tester

The High Frequency Reciprocating Rig (HFRR) is a microprocessor-controlled reciprocating friction and wear test system which provides a fast, repeatable assessment of the performance of fuels and lubricants. It is particularly suitable for wear testing relatively poor lubricants such as diesel fuels and for boundary friction measurements of . The hybrid PVA hydrogel showed a very low coefficient of friction of about 0.01 in reciprocating friction test in saline solution and appeared undamaged under microscopic observation. Hydrogels similar to natural articular cartilage are required for the development of artificial joints with lubrication mechanism of natural synovial joints.

Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are . Test parameters: friction pair of Si 3 N 4 ball with the diameter of 4 mm, reciprocating speed of 200 times/min, reciprocating length of 3 mm, frequency of 1 Hz, corrosive medium of 3.5% NaCl solution, respective load of 3, 5 and 7 N, and test time of 30 min. The morphologies, chemical compositions and phases of worn track were analyzed using a .

Friction force range: up to 20 N (5 N option) Friction force resolution: 0.06 mN (0.015 mN option) Rotating movement: Speed: 0.2 rpm to 2000 rpm (600 rpm option) Radius: up to 40 mm: Maximum torque: 450 mN.m: Linear reciprocating movement 1) Stroke length: up to 60 mm: Speed: up to 370 mm/s: Frequency: 0.01 Hz to 10 Hz: Rotational reciprocating .

Reciprocating Friction Tester. Model Name-Series. Wear Test Systems. View All View All Series. Data-Manufacturer information. . MTDI develops, manufactures and distributes materials testing and metallography solutions with focus on providing our customers with: Application area Application customer Steel manufacture industry National research .The tester is used to simulate the rotation and linear reciprocating motion under a certain test force. It is tested by controlling and changing the test force, speed, frequency, stroke, time, friction partner material, surface roughness, hardness and other parameters to evaluate the comprehensive performance of the material or surface coating. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done .

tacklife soil tester 3-in-1 soil moisture meter for moisture

tacklife wm01 classic wood moisture meter user manual

WEBTire as suas dúvidas aqui! Explore a nossa biblioteca e tenha suas dúvidas respondidas .

Reciprocating Friction Tester solution|linear wear friction testing